An ounce of prevention is worth a pound of cure. Doctors, nurses, and other medical professionals are personally aware of the cruel truth that the lives of many patients “might have been saved” if the right medicines were available – and affordable. The same is true in homeland defense. The cost in dollars of the 9/11 attacks on the World Trade Center has been estimated to be “$1 trillion, and counting.” How much the lives of the more than 3,000 innocent people killed in those attacks were worth is a cost that is truly incalculable. This Special Report on personal protective equipment focuses on some of the life-saving garments and PPE systems now available.

An ounce of prevention is worth a pound of cure. Doctors, nurses, and other medical professionals are personally aware of the cruel truth that the lives of many patients “might have been saved” if the right medicines were available – and affordable. The same is true in homeland defense. The cost in dollars of the 9/11 attacks on the World Trade Center has been estimated to be “$1 trillion, and counting.” How much the lives of the more than 3,000 innocent people killed in those attacks were worth is a cost that is truly incalculable. This Special Report on personal protective equipment focuses on some of the life-saving garments and PPE systems now available.

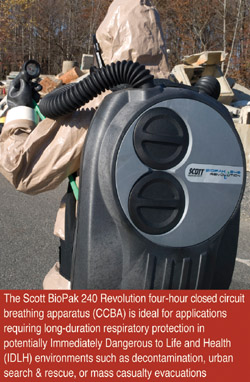

Scott Health Focuses on “Lowest-Cost” Long-Duration Respiratory Protection

Homeland-security professionals working in what are called IDLH (immediately dangerous to life and health) environments would be particularly interested in any PPE gear or equipment item that helps them breathe more safely, more easily, and for a longer period of time in such environments.

That is exactly what the Scott BioPak 240 Revolution provides – long-duration respiratory protection – said Marty Lorkowski, industrial marketing manager-Americas for Scott Health. The “best option” for working in hazardous, “potentially IDLH, environments,” he told DPJ, “is a four-hour re-breather.” His company, he continued, “offers the most advanced re-breather on the market today.” He described the Scott Biopak 240 Revolution as “a closed-circuit breathing apparatus [CCBA] that will provide 240 minutes of oxygen” – enough, he pointed out, to keep the wearer “safe and comfortable during long wear times,” such as those likely in mass-casualty evacuations.

In addition to the BioPak 240 and other CCBA units, Scott offers a number of other “respiratory solutions” for homeland-preparedness professionals, including CBRN (chemical, biological, radiation, nuclear) APR (air-purifying respirator) and SCBA (self-contained breathing apparatus) systems, Lorkowski said. Of particular interest to decision makers and budget analysts at all levels of government, he pointed out, is that Scott “always” offers “the lowest cost of ownership” for all of its SCBA systems – including, he emphasized, “the BioPak 240 Revolution.”

SafetyTech’s C-625 PAPR Critically Needed To Meet All-Hazards Bio-Preparedness Act

SafetyTech International, which counts the U.S. Special Operations Command, the Federal Bureau of Investigation, Army Medical, and a growing number of other U.S Army and U.S. Navy commands among its satisfied customers, was designing, developing, and manufacturing first-receiver and first-responder protective PAPR (powered air-purifying respirator) products even prior to the terrorist attacks on American targets on 11 September 2001. A number of the nation’s largest hospital systems also are long-time customers, and several have identified the company’s new C-625 Multi-Hazard PAPR System as a “critical need” if they are to be able to cope with future emergency-response incidents and events.

The C-625, which is one of several “loose-fitting” Safety-Tech products that comply with the All Hazards Bio-Preparedness Act of 2006, was specifically designed for use  in multiple-response situations, said Jeff Paden, the company’s sales & marketing director. Its “one-size-fits-all” hoods and “unique” audible alarms (for low-flow or low-battery) provide significant flexibility. It is precision-molded and resistant “to all chemical-warfare” agents, Paden said, and is designed to be offered “with a variety of filters, cartridges, and canisters.” The loose-fitting systems and single-sized hoods, he pointed out, not only “eliminate fit-testing” but also simplify logistics. In mass-production quantities, of course, those bonus factors also should lower costs, as most government and private-sector customers would quickly recognize.

in multiple-response situations, said Jeff Paden, the company’s sales & marketing director. Its “one-size-fits-all” hoods and “unique” audible alarms (for low-flow or low-battery) provide significant flexibility. It is precision-molded and resistant “to all chemical-warfare” agents, Paden said, and is designed to be offered “with a variety of filters, cartridges, and canisters.” The loose-fitting systems and single-sized hoods, he pointed out, not only “eliminate fit-testing” but also simplify logistics. In mass-production quantities, of course, those bonus factors also should lower costs, as most government and private-sector customers would quickly recognize.

Thanks to its extensive experience and its already impressive customer base, SafetyTech has become, in Paden’s words, “the acknowledged world leader in CBRN PAPR design, development, and manufacturing.” The company’s products, he continued, are used by numerous U.S. government agencies for a broad spectrum of missions ranging from counter-proliferation programs to maritime interdiction and port security. In addition, Paden said, various SafetyTech products have been “extensively specified for use in mitigating the consequences of CBRN [chemical, biological, radiological, nuclear] events.”

Several U.S. military after-action reports, carried out in the wake of the 9/11 terrorist attacks and verified by later CBRN exercises, confirmed what SafetyTech had already concluded – namely, that multi-hazard PAPR systems such as the C625 would be particularly useful in carrying out “laborious response and decontamination missions.” Laborious, of course, means not only time-consuming but also manpower-intensive, and both of those negative qualities translate directly into higher costs for the American taxpayer.

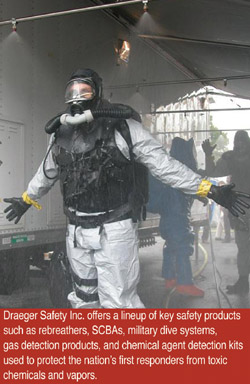

A Winning Combination for Draeger: Quality Training & End-to-End Solutions

Today’s emergency responder has to be prepared to cope with a number and variety of minor and major catastrophes of all types – including, in some instances, certain situations not included in the standard training manuals. It is in large part for that reason that Draeger focuses considerable attention on PPE equipment that enables responders “to be prepared for the unexpected.”

The company’s new Combination breathing apparatus, designed for front-line responders who are carrying out tactical operations, is a case in point, said Greg Farmerie, Draeger’s business development manager, Defense & Security. Members of SWAT teams who are involved in a “first entry” assignment use a Combination system, he said, because it allows them to focus full attention on “other areas of their responsibilities.”

The Combination system allows the user to switch from compressed air to a powered air-purifying respiratory (PAPR) system while working in contaminated or potentially contaminated zones or environments. That capability conserves air, extends the on-scene time available to the individual responder, and makes the initial response operations both faster and more effective.

The Combination system is used not only by Department of Defense units assigned to carry out CBRN (chemical, biological, radiation, nuclear) reconnaissance operations, Farmerie said, but also by local fire departments and both state and local law-enforcement professionals. Draeger’s BG 4 rebreather, on the other hand, is probably a better fit for individuals and units involved in analytical operations – e.g., those working in hazardous operations and recovery work after an incident has occurred.

“We offer end-to-end solutions in two core competencies,” Farmeries said: “CBRN breathing protection, and the detection of hazardous gases” – including those emitted by toxic industrial chemicals, chemical-warfare agents, and biological agents. In keeping with that philosophy, he continued, Draeger’s “total capabilities” include working in close cooperation with fire departments and police departments not only in providing and maintaining their equipment but also in carrying out the “quality training” needed for operational effectiveness.

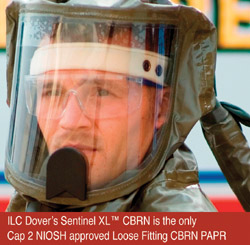

ILC Dover Rounds Out First-Responder Ops By Focusing On Protection for MCI Victims

The emergency-management guidelines for coping with mass-casualty incidents (MCI) of any type almost always start, understandably, with the same logical mandate: First, protect the first responders themselves – i.e., the firefighters, emergency medical technicians, policemen, and support personnel who are on the scene, sorting through the rubble, maintaining order, and putting their own lives on the line to save the lives of others.

ILC Dover, which has a long history of designing and producing protective masks, hoods, and other chemical/biological protective equipment for all branches of the nation’s armed forces, does not disagree with that mandate. But it carries it a step  further by paying special attention as well to the development of easy-fit PPE units that save the lives of those who are caught in the rubble, who might be unable to escape without the help of others, who might even be unconscious – who are, in short, the MCI victims that the first responders are trying to save.

further by paying special attention as well to the development of easy-fit PPE units that save the lives of those who are caught in the rubble, who might be unable to escape without the help of others, who might even be unconscious – who are, in short, the MCI victims that the first responders are trying to save.

The company’s SCape® CBRN(30) – which already has been approved by NIOSH as an escape respirator – has several features that, in the words of National Sales Manager-PPE Tom Grassso, make it “a true one-size-fits-all” unit that starts to operate “the minute the product is removed from its container. There is nothing for the users to do than remove the product and put it on.”

Dover also offers a Sentinel XL™ CBRN chemical-preparedness variant of the system that is fitted with a butyl rubber hood and an unprotected (but very lightweight) breathing hose that make it particularly valuable for use in pandemic preparedness and the control of infectious diseases. Among its special features are a combination low-battery audible and visual alarm system that activates when the battery life is running low and a head cover that permits use of a stethoscope.

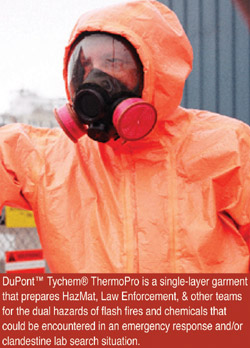

DuPont’s Global Heritage Of Quality: Working Today To Protect Tomorrow

It is not surprising that DuPont was one of the first companies the federal government turned to in the post-9/11 efforts to design, develop, and produce the broad range of PPE gear needed, in massive quantities, by the nation’s first responders to protect the U.S. homeland in the Age of Terrorism. For many decades, the company has been a world leader in building a wide range of quality products not only to meet Department of Defense needs but also to protect the lives of the nation’s firefighters, policemen, and emergency medical technicians who are first on the scene of a domestic incident or event – whether natural or manmade.

and emergency medical technicians who are first on the scene of a domestic incident or event – whether natural or manmade.

DuPont has earned global respect for not only the quality of its long and ever-improving line of protective garments but also for the flexibility, versatility, and adaptability of those garments – as is evidenced by four of the company’s best-known products: DuPont™ Nomex® fiber to cope with thermal hazards; Kevlar® fiber for ballistic, stab, cut, and abrasion protection; Tyvek® garments to provide dry-particulate protection; and Tychem® garments to protect against toxic chemical and gas hazards.

In the field of domestic preparedness, one of the company’s most important PPE offerings is the Tychem® ThermoPro, an ingeniously designed product that, as described by Jeff Jung (the company’s North American Segment Manager, Emergency Response), provides “protection from dual hazards – flash fire and chemicals – in one single-layer garment.”

Proven quality, superior distribution and logistical support, and leading-edge products – DuPont has earned its reputation the hard way: by working hard every day, for over 200 years, to help meet the needs of all who need protection, whether from fires, natural disasters, chemical spills, or outbreaks of infectious disease. But the company is not done yet, Jung said. DuPont scientists and designers are now exploring “a variety of new offerings,” he said, including membrane technology for chem/bio protection, improved-design chemical protective garments (“to facilitate donning and doffing”), and several fire-service products designed “to improve thermal insulation” and otherwise enhance “firefighter performance.”